From OOG equipment to critical parts, Freight Right supports dozens of mines worldwide.

The mining sector is marked by its unique complexity and demands, especially in logistics. Overlooking the supply chain can lead to significant financial losses for mining companies. Optimizing your logistics not only streamlines operations but also unlocks substantial savings.

Partnering with a logistics expert like Freight Right, adept in mining equipment transport and the nuanced challenges of mining logistics, can transform your supply chain into a streamlined, cost-efficient system.

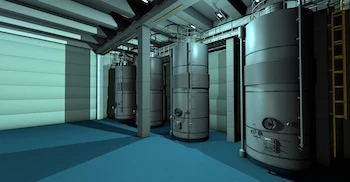

The mining industry involves transporting oversized equipment like excavation machines and hefty materials, which often exceed standard size and weight limits. Leveraging a seasoned 3PL's network can mitigate the high costs and complexities of such shipments, including hazardous materials, ensuring compliance and safety at every step.

The isolated locations of mining sites add layers of risk, particularly theft and damage, to transporting valuable minerals. A proficient logistics partner provides vetted carriers and scrutinizes insurance policies to shield your assets from unforeseen losses, ensuring peace of mind.

The remoteness of mining sites poses logistical hurdles, limiting carrier options and inflating costs. Freight Right Global Logistics expands your reach, connecting you with a vast network of reliable carriers, optimizing routes, and enhancing service levels to support your operations efficiently.

Freight Right Global Logistics brings extensive experience in industrial and mining transportation, adept at navigating the challenges of remote locations and sensitive shipments. Our case studies in regions like CIS, EMEA, and the Americas showcase our capability to manage mining logistics effectively, ensuring your operations run smoothly.

In 60 days, the mining logistics team at Freight Right moved oversized and heavyweight equipment from different plants in southern Africa onto a vessel that sailed north along the coast of Africa, through the Strait of Gibraltar, across the mediterranean sea to a port in the Black Sea, where it was then transferred onto 23 specialized chartered trucks and moved to the concrete wall that marked the border between the country the equipment arrived in and where the mine was. Here, our team, along with customs agents from both countries oversaw crews disassembling the border wall in order for the equipment to pass through and onto the destination, the mine.

This was no small logistical undertaking. Our team leveraged their knowledge of moving specialized equipment, relationships with properly equipped carriers, and international repute with customs agencies in order to complete this complicated task.

To carry out this unusual task, the team used the full scope of tools available to them, like road surveys, state police escorts, and more. To ensure quality and a smooth process, members of our mining team even traveled to the site and personally administered every step of this logistical process.

As a result of Freight Right’s efforts, the mining machinery and equipment reached its destination, where a major mine operation was underway, safely and on time.

Contact us to learn more about our mining services and talk to an expert about how Freight Right can streamline your mining supply chain.