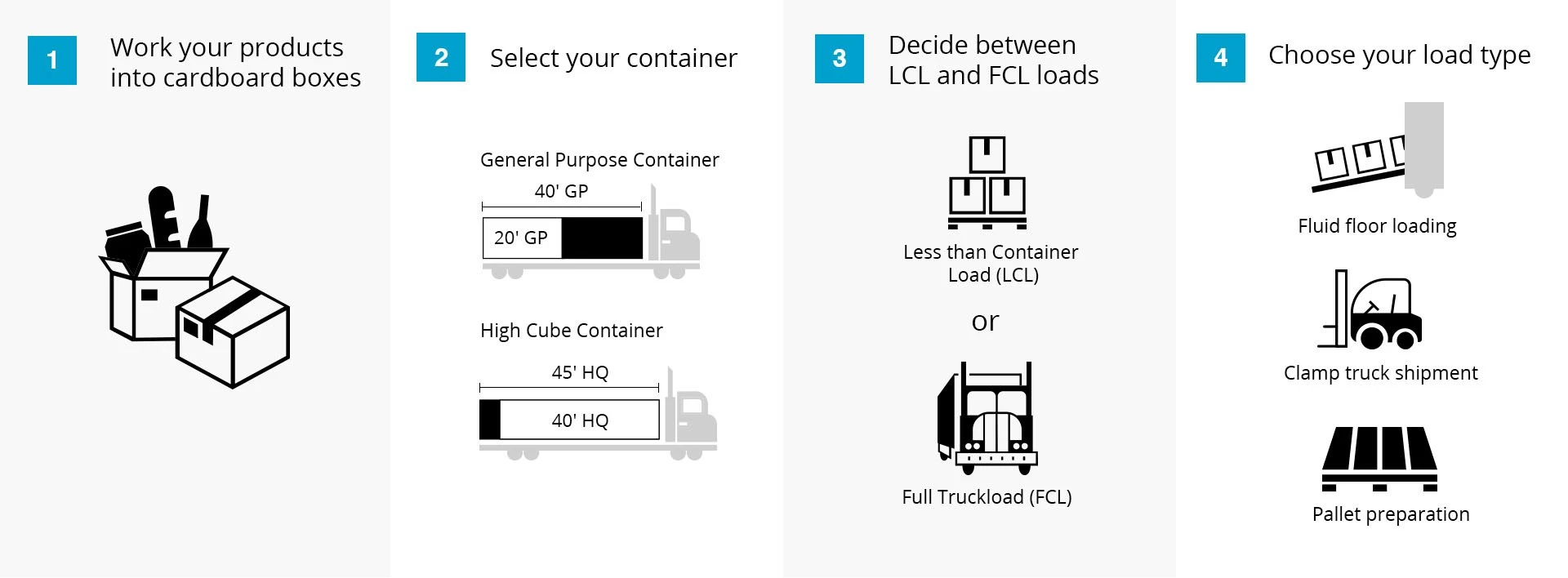

In this guide, you will find out the step-by-step process of how to prepare your full container load (FCL) and less-than-container load (LCL) packages and containers for an Amazon FBA deliveries.

General purpose container

Full Truckload

Fluid floor loading

Clamp truck shipment

Pallet preparation

1. Make sure your container have an internal height of at least 8' or 90" or 2.31m

2. Create shipment plans in Amazon's Seller Central

3. Print FBA shipment labels

4. Book the shipment with the carrier

5. Verify that the container floor is well-maintained, free from obstructions or damage, and safe for transportation. The floor must be able to endure the weight of a fully laden pallet jack.

*the use of containers with uneven or corrugated floors, like refrigerated containers, are not permitted due to safety concerns.

6. Follow the regulations prompted by the U.S. Department of Transportation (DOT) regarding container axle weight and total gross weight restrictions.

Maximum weight for 20 GP containers is 37,500 lbs or 17,025 kgs.

Maximum weight for 40 GP/HQ containers is 44,000 lbs or 19,958 kgs.

Maximum weight for 45 HQ containers is 46,000 lbs or 20,865 kgs.

1. Sign in to Amazon’s Seller Central

2. Follow Amazon’s FBA packaging and prep requirements to prepare product units

- Print your Amazon Standard Identification Number (ASIN) barcode* labels from Seller Central.

* The barcode will start with B00 or X00 and will be unique to one specific product

Example: There is a different ASIN barcode for each product variation (color, size, etc.). You can also enter UPC barcodes if they correspond with the correct ASIN on Amazon.

- Make sure that your ASIN barcode is easily scannable, then attach it to the exterior of your product*

*Refer to ‘Label Products’ in Seller Central ‘Help’

- Include the expiration date of your product on each individual unit

- Include the expiration date of your product on each master carton which will be expiring with:

Font size 36+

Format the date: MM-YYYY or MM-DD-YY

- Products will be destroyed if:

They are expired

They will expire within 90 days*

*The same ASIN within the same case or pallets must contain the same expiration date

*The master carton must have an expiration date as well

- Prepare and Label any products that require special packaging like:

Sharp items (cutlery, knives, or sharp-edged decorative objects)

Glass / fragile

Apparel / textiles

Dangerous goods (HAZMAT)

Plush products - small products

Baby / adults

1. You are to only send standard-sized (sortable) ASINs in fluid floor loaded shipments.

Do not allow individual unit sizes to exceed:

18’’ x 14’’ x 8’’ OR 45cm x 35cm x 20cm for standard-sized ASINs

20lbs OR 9kgs

Place all individual units in boxes

All boxes shipped to a Sortable Fulfillment Center (standard size products) must not measure any more than 25’’ or 64cm on each side - Large or oversized products* can be placed in larger boxes

*If you have oversized product units (individual units over 20 lbs or 9kgs), prepare them on pallets or have them clamp truck enabled. *Check “FBA Product Size Tiers” information on Seller Central

2. Do not allow for your boxes to exceed 50lbs or 23kgs of sortable products in a fluid floor loaded shipment

Pack the same ASIN in each box

Mark the boxes as ”Case Packed”* *You can pack multiple ASINs in the same box, but no more than 5 different ASINs are recommended to be placed in the same box

Make sure your packing list meets the FBA Packing List requirements

Load boxes with different ASINs inside the container by loading all the boxes related to the first ASIN, then load all the boxes related to the second ASIN, and so on until the container is loaded.

Print box labels (Ship From, Ship To, PO # with barcode) Place the box label in an easily visible location on the box (side or top)

Only use large-sized dunnage (air pillows, full sheets of paper, bubble wrap, sheet foam)

Do not use loose fill of any sort (styrofoam, peanuts, or shredded paper)

Stack all boxes into columns. DO NOT bundle boxes together with straps, zip ties, tape, or other products.

When loading the container, use air pillows, diamond corrugated, or dunnage to maintain stability

Prevent difficulty during the unloading process, do not force boxes into smaller spaces

Plan to have at least 8’’ or 21 cm of space between the container door and the last row of cartons

Use load bars and straps to properly secure all shipments

It is part of the shipper’s and carrier’s responsibility to make sure that shipments are loaded into a trailer in a way that will prevent the load from shifting or breaking during transit

Q: What are clam truck shipments?

A: Clamp truck shipments are special floor loaded shipments received by Sortable FC’s (standard size products) and Non-Sortable FC’s (oversized products).

Checklist

1. Arrange each column to be uniform and aligned with the other tiers on the base of the column. This is to make sure that all four sides of the freight column stack can be safely squeezed by the clamp.

2. Make sure that columns are at least 24’’ or 61 cm wide and maximum 72’’ or 183 cm long.

3. Do not exceed the column maximum clamp weight of:

3000 lbs or 1360 kgs if the load is not elevated

1300 lbs or 590 kgs if the load is elevated (double-stacked load)

4. Allow at least 3’’ or 8 cm of clearance from the above the box to the container roof

5. Use air bags to allow at least 3’’ or 8 cm between container stacks and walls. This is to prevent the load from shifting or falling.

6. Leave at least 3’’ or 8 cm between each column of boxes*, and use airbags to maintain load stability during transport.

*DO NOT bundle boxes together with straps, zip ties, tape, or other products.

7. Allow for at least 8’’ or 21 cm of clearance from the last row of cartons to the container doors to engage a dock traveler

8. Use load bars and straps to properly secure all shipments

- It is part of the shipper’s and carrier’s responsibility to make sure that shipments are loaded into a trailer in a way that will prevent the load from shifting or breaking during transit

1. Place FBA shipment labels on each carton

2. Use 40’’ x 48’’ OR 1.02 m x 1.22 m, 4-way access, wood pallets*

- If a single, large unit does not fit on a 40’’ x 48’’ pallet without hanging over the edges, use a pallet type and size more suitable for that unit

3. Whenever quantities allow for it, stack only one ASIN per pallet- label these as “Single ASIN Pallet”

4. Only use pallets that are compliant with GMA Grade B or higher, and are made of only wood materials*

*Ship grocery or food products on GMA 1A grade pallets

5. Stretch-wrap all pallets with clear plastic. DO BOT wrap it in opaque or black stretch-wrap.

6. Do not exceed the pallet size:

Height of 72’’ or 1.82m

Weight of 1,500 or 680 kgs

7. To protect and maintain the stability of pallets while in transit, use corner boards

8. Only use double-stacked pallets when they are safe* to load or unload and will not cause damage for the products while in transit

*It is considered safe to double stack pallets when the height does not exceed a maximum of 100’’ or 2.54 m.

9. Make sure that the maximum gross weight of each box does not exceed 50 lbs or 23 kgs unless a single unit weighs more than that

10. Heavy units between 50 lbs (23 kgs) and 100 lbs (45 kgs) must be clearly labeled as “Team Lift” on all cartons.

11. Clearly label heavy lifts above 100 lbs (45 kgs) as “Mech Lift.”

1. Allow at least 6’’ or 15 cm of clearance from the top of the pallet to the container roof.

2. Use air bags, non-metal straps, or a safety net to allow stability during transport.

3. Allow at least 3’’ or 8 cm between container stacks and walls, while in transit.

4. Stack all cartons evenly and do not allow boxes to overhang from the pallet

5. Allow at least 8’’ or 21 cm of clearance from the last row of cartons to container doors to engage a dock leveler.

1. Attach special labels to heavy products over 50 lbs or 23 kgs

2. Attach warning labels on specialty products

3. Do not prepare fluid floor loaded shipments with cartons that weigh over 50 lbs or 23 kgs

- Oversized units and cartons have to be palletized unless the load is clampable

4. Adequately stack pallets, allowing enough space for unloading.

5. Stack clampable shipments with at least 3’’ or 8 cm of space from the load to the roof of the container.

6. Always secure the load with air bags, non-metal straps, or safety nets to avoid the shifting of the contents during transit, which can cause damage to the products.

- Please note: Containers that do not comply with the aforementioned protocol and Amazon FBA requirements, may be rejected. In that case, you will be responsible for additional storage, re-work, and re-delivery charges.

Factory address

Delivery address (If delivering to Amazon FBA, please provide the 4-digit Facility Code)

Description of goods (Include HS Code if available)

Value of goods

Advise if you have imported to the United States before

Do you have a continuous customs bond?

How often do you import to the U.S.?

How often do you plan to import in the next year?