For the full interview, visit our YouTube. For audio only, visit our Soundcloud.

Robert

All right, so everybody talks about the vessels, right? 60 vessels, 90 vessels, 100 vessels. I mean, what does it mean? It's really important how many vessels we have? And where is the real problem?

Tuck

See, I believe, personally, it's not a matter of the vessel, but it's a matter of certain issues that have to come together. We're talking about chassis equipment issue, right? Chassis to move all these containers. There's just not enough chassis within the market to move all these containers on the vessel that are sitting out there. I believe there's half a million containers there waiting to birth and get unloaded. At the same time, we don't have enough warehouse capacity. I believe at all the warehouse locations - Inland Empire, East Bay; any warehouse locations, it's full of cargo ready, it's full of inventory. So even if we can discharge all the 60, 90, 100 vessels within a week, they're not going anywhere, they're just going to be still stuck at the dock, because we have nowhere else to receive them, we have no equipment to move them off the dock. So, it's more complex than the terminal working 24 hours a day, 7 days a week to unload these containers. And at the same time, we all know that the terminal themselves will not have enough space to store all these container. It has to move it has to move off their facility.

Robert

There's some misconceptions out there, right? A lot of what you hear and read in the news is that, ports are the bottlenecks. In some ways they are, but it's not really a labor issue, right? I mean, like you said, you can unload all these containers, but what are you going to do with them, even if you could 35% of the containers that unload in LA and Long Beach, are supposed to go to the Midwest by rail, and they just aren't moving.

Tuck

Labor is an issue, but it's not the main issue. It's not the main driver that causing this congestion. I believe there's multiple issues. I said about chassis; I said about warehouse being full. I'm sure they have to start training people to bring, to get more workers in place. But also rail is a big issue - a big piece of the equation. If the rail can't receive these containers, all those loaded containers are stuck at the terminal taking up space. So we have multi-pronged problems that we have to solve. I don't know how you're going to solve it. But I think, each company themselves: as a trucking company, as a freight forwarder, as an importer, BCO; I think everyone has to kind of come up with their own solution that works.

Robert

Obviously there is no silver bullet. I don't think the federal government or any other government agency can step in and make a change where the problem just goes away. So it's, basically up to the market; up to the party's; up to the truckers; up to the freight forwarders; the yards. So is it going to be driven by economics? I mean, are you making changes because it's hurting your business? And that's how we're gonna get out?

Tuck

Exactly, I believe it comes down to innovation, I think people have to find a solution to the problem, right? I believe we can't just sit there and say, this is the problem. We already in this problem as a trucking company, we end up actually taking less business during the pandemic, even though there's a lot more volume because we realize, if we start taking on more volume, we face the same problem, we face this logjam that we can serve as our client, we can pick up the cargo on time, we can't, we don't have enough chassis to service these containers. Nor do we have the time to return the empties, you have to kind of find our own solution that worked for us.

Robert

So the pain points. I mean, it sounds like a very painful transition not for you, per se, because you can say it's too messy. It's too complicated. I can't manage more, I can't take on more business. In fact, I'm going to cut back on business and perhaps make the numbers work by charging, you know, congestion fees or crises are increasing for everything right ocean freight being at $17,000. Obviously drayage is not going to stay the same. So you can make this work for your company. But I mean, you're cutting capacity, essentially, at a time when we need more capacity, right? So for BCOs; for importers to catch up. It's going to be a painful few months for them to adjust and realize, we don't get capacity. Trade capacity is down. Warehouse capacity is down. So therefore we have to taper our imports. But by the time they do that, some of these large retailers write their POs like a year ahead or six months ahead, and when they can just go and cancel production and not to mention all the small and medium companies who can't even afford that. I talked to customers all the time who already paid for the product and it's not making it to the Christmas season. I talked to a customer yesterday 30% of their containers are missing the Christmas deadlines. I mean, what are they to do?

Tuck

It's tough. If I was in that position, basically, you can have to call it a year. Now you can have to call it a year and stop ordering. People cannot stop buying. And that's why we face this problem. People cannot stop purchasing goods. And that's why we have 60 vessels; 70 vessel waiting in the dock, because we put we bought all these goods and they knew they can sell it because everyone wants to buy something. Everyone's fixing their house upgrading this; upgrading that; we're not spending money elsewhere.

Robert

But is it a temporary spike? Because, you know, I spoke to somebody the other day, and they were telling me port infrastructure was never built to have this kind of capacity. In fact, they never had capacity to handle any kind of disruption. And I'm thinking this is free market, right? Why would you have extra capacity? It's not even just in time. I mean, just in time, it's more on the side of procurement; purchasing and shipping when you need it. But you as a trucking company, you don't sit there and thinking, "I'm going to need 30% more capacity. If things go wrong, therefore, I'm going to buy 30% more trucks or hire 30% more drivers". I mean, why would you do that? Why would there be this as the norm - do we need to build up capacity? I mean, are you building up capacity?

Tuck

I would love love to build capacity. But there's our supply chain issues like in terms of getting like your facility to park our trucks to park these containers, even those facilities are all taken up. Because we have so much containers right now that that a lot of the carriers, they're buying our bigger yard facility, or they're renting our long term yard facility that we use to park our containers at and that we didn't have access to that anymore. We'd love to have more drivers to our fleet, we would add. But the problem is that we would have no place to park besides waiting seven months to get a tractor, right because of issues and all this stuff, we do think that there are there's going to be a need for more truckers or more drivers in the near future. But we just can't do it. We can't do it.

Robert

So you're running a successful trucking company and you're growing and you want to build it up and you want to build up capacity. But I guess my question is, are you building up capacity? Because you're growing? Because you're running a good business? Or are you planning to increase capacity because you think this volumes are sustainable? This is how we're going to this is how much stuff we're going to buy as a country moving forward.

Tuck

This capacity is normal. I think it'll subside, just like our inflation fears will subside once the price starts coming in. I don't think the volume is gonna stay at this elevated level like 30%. But I believe it's like a 30% increase. I don't think that that is unrealistic. I just don't think it's possible. The reason why I'm looking to grow my trucking company is because I believe there's a there's still a shortage. I want to say shortage of drivers. But there is a need for more drivers. More port drivers.

Robert

Is there a shortage of drivers? Everybody keeps saying there's a shortage of drivers. This is like blaming labor, there's a group of people that blame labor. And there's a group of people that always say there's a shortage of drivers. A lot of people a lot of truckers I talked to they don't they don't have a shortage of drivers.

Tuck

If you don't have enough drivers to transport cargo, I understand there's a shortage of driver when when you put out an order and no trucking company wants to pick up that order because they don't have any available driver. You would call it a shortage of drivers. But then when when you're in the offseason, and you have like 30% of the drivers not have been able called in that day for work, because there's no container, is there a shortage of drivers? Right now there's probably a shortage because there's probably more containers than enough drivers to pick up.

Robert

So in normal conditions. And there haven't been normal conditions in logistics in a long time. So yes, but but let's say in 2019 was there a shortage of drivers for harbor trucking?

Tuck

I would say it was difficult for us to to hire drivers to hire qualified drivers to get them on board. And even when we were able to get onboard drivers, they would leave whether it was for higher pay or have a job placement that they suits them better. We've always been able to handle all of our work that we were given, but at the same time we have reduced the amount of capacity that we've been handling like our volume has gone down.

Robert

Tell me about old trucks because I heard a few times in the last couple of weeks. People complaining that it's the clean truck issue that's contributing to this problem. I mean, I didn't see that coming I didn't think that was an issue you were they to, let's say tomorrow, they announced that they're going to allow all trucks to go into the port. Because you know, you can't go into the terminals, if it's older than what's 2011?

Tuck

I believe it's 2011, I think those are gonna get phased out in 2023.

Robert

So let's say they allow a bunch of trucks made in 2005-2006 to go into the terminal, is it going to change anything?

Tuck

I don't think it's going to change much. There might be some drivers that that will be able to bring in the trucks. But a lot of the drivers that have these older trucks, they're like the old owner operator model, right? They, they have these trucks, and they already paid it off. And it's worth it for them to work because they have no lower overhead, you know, but I don't know if it's going to make that big of a difference, because a lot of them, either they stop, they sold their tractors, or they decided to leave the industry altogether because of this clean truck initiative.

Robert

So but so this happened a few years back this 2011 requirement, bunch of truckers left, at least the harbor trucking. So the question is, are there truckers sitting around to come back? And don't you have like a chassis issue? Or how does it help if you have more drivers that still don't have chassis?

Tuck

It's like a rope that's been tangled and there's just knots and knots. And it's really going to be a slow process, you have to untie one knot first, then you have to untie another one before you can fully separate the cord. And I think that's where we're at. We're in that, that situation where where we have a lot of issues we have the warehouse likes being forced to the using these containers that are sitting on chassis as storage. So I'm not just blaming the warehouse, like, the terminal, they may not have the yard facility to unload these containers. So are they're not taking empties back because they're the yard is full. You have truckers that may not have enough drivers or have enough capacity to to plow fast enough or return empty fast enough. But I think it's a multi issue problem that we're we have, and it's going to take a long time, I think it's going to take a while for us to kind of enact it, and get it straightened out. And I don't know, even after we straightened it out, would it go back? Would we not ourselves again, because we have this problem and 2020 in August or September, and it came back and it's even worse now. It's even worse. Now, once we clear up this congestion and it is backlog are we gonna go in 2022? Are we gonna have the same issue again, that is really worse, and come to a point where it's just gonna stop. There's a virtual stop there. There's no movement.

Robert

So is there a risk of full stop? Because there's always a risk of complete gridlock because it's almost like it's clogged. And you have to to unclog something, you don't really have to get rid of the whole problem. You just have to reduce the problem by a percentage. But is there a risk of like full clog?

Tuck

Our economy would it be a lot of trouble this happened, there's so much commerce moved to the ports, that LA Long Beach that I think we control like Long Beach and LA together, I think 30 to 40% of the imports coming in. I do not think there's gonna be a total stoppage. I think sometimes they may have to stop certain aspects of it to unclog like one aspect of the terminal if they stop unloading vessels, so they can move out these empties in order to receive all these empty so they can load it onto that so it's like getting free of chassis, then they can unload full these vessel with cargo and put them on chassis so they can move out that's something that they may be able to do like certain aspects of the industry may stop temporarily so they can unclog you know, but I don't think it's going to completely stop.

Robert

Tell me about terminals. We did a ports tour recently just happen to be on a Saturday and you don't see anything moving around. There's just no life. I mean the only thing and we did this we chartered a boat right so we're we watched it from like the outside from the water looking into the terminals and the only place where you see anything moving is LBCT, which is of course is automated, right? So why isn't there any operations happening on the weekends or at least that we could see? And I was there on Saturday too, but we're driving around and you don't see a lot of stuff happening.

Tuck

Not all terminals are open on Saturday, I believe only a few I think LBCT one of them I believe at that time when when you probably went on the vessel cruise like they wanted Long Beach terminal I think TTI is the one that would be open trade path is one of the few.

Robert

Why aren't they open? Is that because people again going back to people accusing or pointing at labor, right and then they're saying okay, why haven't been they working 24/7? Because Long Beach and LA Port complex (one of the largest in the world) is probably the only the one that doesn't have 24/7 operations. Everybody else in the whole world is 24/7. It just never stops. Why do we stop?

Tuck

I don't know - we only had a second shift when pier pass started. We only had a second shift because it used to close at five. So we didn't have a second shift. I think it will take time for the industry to adjust. Just like pier pass, right? Like, like when pier pass was proposed? A lot of truckers said, "Where am I going to get drivers to work second shift?", Who wants to work at night? Like there's there's always these these issues to work at. And it has to kind of filter through the industry through the supply chain for people to say, hey, is there a benefit for us to to work the second shift? Sometimes they create an artificial problem like they wouldn't give you appointments until second shift for you to do to come pick up your container.

Robert

That's not happening now with 24/7 operations, right? It's not like now you can go pick up containers at night because you still have an appointment.

Tuck

Yeah, you need an appointment. We tried Saturday operations one time. It's hard to get drivers to come work on the weekend.

Robert

Because these are drivers who already work.

Tuck

Yeah, they already worked 40, 50, 60 hours depending on the week, right? They're tired, they want to spend the weekend with the family. Like if they want to really go over the road, they probably make a lot more money than than working the ports, I believe.

Robert

Do you gain anything by moving drivers from weekdays to weekends? Or from daytime to nighttime and lose the capacity of daytime?

Tuck

There's no added benefit. If there was an added benefit, I would have moved drivers to the weekend and ask them to come in to work on Saturday, make a little shift and have driver work on Saturday. But there's no additional benefit and actually create more of an issue. Because the times that we do work on Saturday, customer service is slow. Sometimes there's issues at the terminal. Like, if you have a problem, it's hard to reach someone you can't deliver continued use. And so you would have to pick it up and store it in your yard, taking up additional valuable storage yard space, which we have a really limited amount.

Robert

Let's talk about empty return because this is for customers, this is the most painful point, they can't get their product out. And they paid $20,000 for the container. And they can't get it out. And once they get it out, they unloaded assuming their warehouse somehow makes space and then now you can't return these empty containers; they end up paying per diem which is to cut down a little bit on the jargon is basically detention for not returning the container. Depending on the carrier and the contract, you have, you know, 5 to 10 days maybe to return the empty container. If you can return it the customer pays, $200-$300 a day maybe more and but it's not their fault - you can't return the empty. So how big of a problem is this?

Tuck

You have to really jump over hoops in order to return empties. It's not impossible and it's not that they're totally going to lock you out for an extended period of time. Most carriers they know because they're going to open up certain receiving like whether it's the terminal or the carrier I'm not sure who controls such things together as a unit they decide when they're going to open up empty receiving, but it's not impossible to return empties; but you have to jump over hoops.

Robert

So just working the appointment system trying to get as soon as the appointment opens up you try to grab it but there isn't enough appointments. Long Beach, you see empty containers dumped pretty much on the street getting ticketed because they don't have any place to put them and they can't return them like overall there is an empty return problem there's just no space.

Tuck

In an ideal world, the carrier would let you return an empty without an appointment. If you have an empty, you just drive into the terminal and drop it off. I think that's how it should be. Why should us or the importer be forced to store empty because the terminal itself or an extension of the carrier does not have space to receive their own equipment back? I believe in a perfect world, or if there's any changes that come out of this, is that we do not need an appointment to return it empty. So basically you just return it empty wherever that that carrier has to designate one or two terminal where they're receiving empties and you just drive in the empty and drop it off and they will receive it.

Robert

But right now they're not taking them because they don't have space.

Tuck

They don't have space. But they are working on it. There's some carriers that are actually doing their part.

Robert

And you would think that they need this empties, or the problem recently, the recent months, or maybe a year and a half has been containers in China; you couldn't get empty containers in China at some point. You had even scalpers, they were charging, you know, $300, to get you an empty container. It's a huge equipment problem in China, because we have all those containers here. So these carrier need these empties to go back. Are these vessels going back empty? Don't desperately need containers? Why are they not loading out more?

Tuck

I don't know the inner workings of the ports or how they run their facility or their yard. From a business person, when when I see that I can't handle enough business, I would reject the business. I reduce my capacity, I reduce the amount of work orders that I take from my clients and say I can't handle this, that I know for sure there's issues right now at the terminal. So I'm not going to take more work than I can handle. And that's been my big issue with the carrier and the terminal. But you know, that you have more work that you can possibly handle properly. Why would you take on all this business? It's just a lack of consideration for your clients. It's really a lack of consideration when you are accepting business because they're paying a high premium for freight. Why didn't you turn away the business and say we can't handle this; turn the vessel around? If you're with a terminal, if you didn't know that, you got to have 60 vessels sitting in the water for months, why didn't you turn back the vessel? Send them back?

Robert

But this is also on the carriers, though, right? Because the terminal maybe says I'm only going to unload this many vessels, so don't send them - but they keep sending them. Okay, then you're gonna have to wait. Because these guys wait a lot longer. Terminals don't want them. It depends on pay. So they're paying tariff rates, they're not contract rates and pay more, so maybe they take them, but these vessels keep coming. I mean, it's this is a terminal that says, ports can only unload 30 or so vessels simultaneously. But if you have more than 30 vessels, they're gonna get anchored. But they still keep coming.

Tuck

I think they just have to stop, they have to stop kind of, kind of slow it down, either anchor those vessel or send the goods back, what choice do we have send the back. Because you keep throwing that you keep rolling more problem to the supply chain. And you might be right, it might come to a complete stop a complete halt. But he barely got it, it's just a trickle, you can only get a few containers out. Right? Like it comes to a point where if they have no yard, the rail cannot move all these IPI containers, these inland container warehouses cannot receive these containers to unload, there's no chassis to move them, no yard to store them off the off dock. What are you gonna do, they're gonna sit there at the vessel, and then there's no more unloading of these cargo vessel. I'm not sure how much space they still have left, that we're still moving cargo in and out of there. And we're returning empties. But I think part of the solution is you got to slow down, like as business during the height of the pandemic, we have so many containers that we can handle take less container for this week when I can accept Agios with this eta for this week, or this month. Until we catch up until we clear out while we have, you know, work that we already accepted that we committed to doing. We slow down, we're not going to accept any more work order. Once we clear that out, then we reset and we start over. That's something that I don't know at least the port. That's the right way to do business. You know, people might disagree with me, but if you can't handle the business, you got to kind of turn it away.

Robert

It still doesn't justify the long voyage to the east coast. So but we are seeing customers routing containers to the East Coast now versus the West Coast, given first of all that the transit time is about the same considering the anchor time but but we do see some sort of tapering to the West Coast. We're also coming to almost the close of season?

Tuck

We don't know yet. There might be a big rush in November. I've talked to a couple of my clients and they expect to have a heavy November and December.

Robert

But this is restocking. It's not Christmas. This isn't Christmas shopping.

Tuck

I'm not sure but they're saying they're going to be heavy in November in December. I think we have to kind of clear up the backlog right now.

Robert

Do you think the key to clearing out this backlog may be downstream in let's say Chicago in Memphis and Dallas? We just need to get some capacity to move containers by rail out of Long Beach?

Tuck

I agree, I think that's not that we have anchor now, if we can move them to Miami to other ports that willing to receive them, I think that's how you're gonna have to do it, that's little, everyone has to have to do a little bit of the part. You can't have like 60, 70 vessel anchor, I wouldn't move them to Canada or wherever they can receive them move as many vessels you can that can receive them. And that would kind of help clear us up once we're clear, then you can reset. And I think that that might be the solution, you know, in Miami solely to offer to receive some of the vessel moves on the vessel over there. I think because we can't I don't think Long Beach and LA is able to handle this, continue to handle this and would more coming.

Robert

Continuing to handle this is an interesting concept. Because they have been doing this for 18 months non stop. Usually they operate at peak season, maybe 100% capacity with like, three, four months out of the year.

Tuck

There's always that peak and valley. They'll work really kind of busy for 3 months. And they'll get a month or two that's kind of a slow down, for them to catch their breath, service all the machines or whatever, re-strategize or whatever they need to do. It's just like us with a trucking company. Right? We because we have to maintain our trucks, we got to fix our truck, we got to have driver training and all this stuff. We got to kind of catch up with paperwork. But when we're constantly going 100 mile per hour, and you have no time to kind of stop or take a break. And that's the problem. I think part of it. I think a lot of the dock is overworked. I think a lot of them are tired.

Robert

Because it's labor, because it's union, everybody tends to talk about, how it's hard to get them to work 24/7 or overtime. But hese people have been working 12 hour shifts for like 18 months now. Right?

Tuck

It's tiring, even though you paid well, after a certain point, it's not about the money. It's about your your leisure time, the enjoyment of life is personal enjoyment. And if you're forced, if you're working five days a week, 12 hours a day, there's no enjoyment in life, you're always working overtime, and you're constantly under the gun from management, wanting you to work over time. That's why even with my driver, I kind of tried not to do that. Like I tried to space out the work like guys that that I see been putting in overtime, I try not to do it for them, like next week or you know, the the following day.

Robert

And let's face it in California, you have like a labor issue everywhere. Yeah, it's hard to find people, it's hard to hire people, let alone people who are going to operate this machinery, right. It's not an easy job. It takes a lot of training. It takes a lot of experience.

Tuck

Part of the issue with their labor, I believe they're going to have to automate. Every terminal is going to have to automate like LBCT. That's the only way for you to operate 24/7 like LBCT, if you have a vessel bursting at LBCT, you look at that, I'm not sure if they're giving orders out the birthing date instead of the ETA. But you know, that whatever that date that's given on the arrival, notice, you know, you can count like clockwork. In two, three days it's ready for pickup. I'm not sure if the fact that it's automated, or if they're just giving the birthing date, their system is so efficient for routing data versus the ETA. However, they're giving it up to you. But I noticed that that LBCT and the vessel like that comes into LBCT I looked at the the under delivery order that we get it has an ETA and I can count out two days it'll be off the vessel; three days at the longest it'll be off the vessel. I believe in order for them to operate 24/7 they have to automate. Most of the terminals need to automate. APM has an automated section now. Tradepack has an automated section, but they always break down.

Robert

A lot of stuff is breaking down now because of the 18 months non-stop workload.

Tuck

I can send you endless emails from Tradepack telling you that they're canceling appointments because they have issues like there's certain areas are closed. And I believe some of those area closes because of mechanical breakdown with their crane or their loader. You can't operate machinery for 18 months straight and not expect it to slow down and you know, you can't constantly have machine work, possibly for 18 months without service. You know, just like our trucks now; it used to when we take in a truck every 3 months for service or repair or at the bid inspection - the next morning we get it back. Now at times it can take upwards of 2 weeks just to get parts like a hose.

Robert

Well, that's because they're anchored down at the port!

Tuck

It is, but that's also the issue too. Getting parts to repair trucks and machines and forklifts and all this stuff. It's also an issue that will slow down the solution that we have to get de-congest and free up the terminal.

Some exciting news from our corner of the logistics world—our CEO, Robert Khachatryan, has been shortlisted for the The LA Times Studios - LA Executive Leadership Awards.

Freight Right CEO Robert Khachatryan joins the E-commerce Coffee Break podcast to share insights on shipping large, heavy, and high-value goods internationally, avoiding hidden costs, and expanding into 45+ markets without a local presence.

Direct-to-consumer merchants selling oversized goods domestically and internationally have a unique set of logistical and pricing challenges. Freight Right's CEO Robert Khachatryan discusses those challenges on Ticker News Australia.

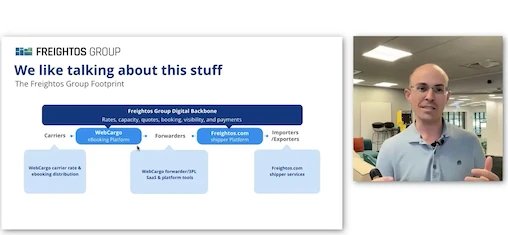

Our CEO sat with Freightos last week to discuss the future for independent freight fowarders.

Rising COVID cases partially closes down one of the world's busiest ports, what does that mean for freight?

President Trump issues Executive Order to stop overlapping tariffs on imports under national security and trade actions, ensuring duty rates remain targeted and non-cumulative. Effective retroactively from March 4, 2025.

Big and bulky fulfillment doesn’t have to block global growth. Learn how ecommerce brands can ship oversized products internationally with real-time freight rates, duty-paid delivery, and zero foreign inventory.

The US imposed a 100% tariff on Chinese-made port cranes to cut reliance on China’s infrastructure, prompting backlash from U.S. ports and retaliation from Beijing.

The International Longshoremen's Association began their strike October 1, 2024, affecting ports running along the east coast and Gulf regions of the United States. See what ports are affected and what this strike can mean for shippers.

We examine how US-China trade tariffs have affected freight and logistics around the world.